What’s the issue?

It is sometimes necessary to implement a capacitive pad on a PCB. There are some very basic rules to clarify the design route – miss them and life can get painful. What follows is only semi-rigorous, but it does give the right rules of thumb for error avoidance.

How do I design the PCB pad and insulation on my PCB so that I can implement a capacitive touch pad?

There are some very basic rules:

- Don’t try to design the electronics and firmware for detecting a touch. It is possible, but you’ll be at it for a while and it will get complex. There are numerous chips on the market for touch sensing from a capacitive pad. The EM recommends that one is used.

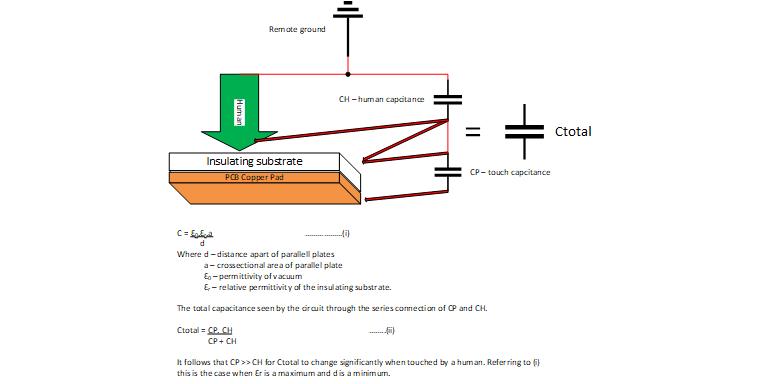

- Note that the whole system approximates to two parallel plate capacitors connected in series (see image below). The PCB pad on the board with an insulating layer above it (the human touching it equates to the other conductor) is the first (CP – touch pad capacitance), and the capacitance of the human connected back to some remote common earth is the other (CH – effective capacitance of a human touching the pad). The system and equivalent circuit are shown in the diagram below with an explanation of function. Read the explanation if you wish to understand why the following statements are valid.

- In order to make the capacitive touch as sensitive as possible, the insulating substrate needs to be as thin as possible, but this may conflict with the requirements of the system for robustness.

- To further improve the sensitivity of the system the insulating substrate needs to have a relative permittivity as high as possible. This is the reason that glass, though delicate and brittle, is chosen for capacitive touch sensitive screens on mobile phones. The glass used on mobile phones is known as Gorilla glass because it is formulated to be as tough as possible even when very thin. It also has a relative permittivity, approx. 8, which is high, consistent and stable. Glass is a good material to choose as long as robust enough – note mobile phones often nevertheless crack.

- To ensure a capacitive touchpad has the maximum effect it should have dimensions at least as big as a fingerprint, but there isn’t much point in making it bigger – the area of the finger touching the insulating substrate effectively defines its active area.

If you have any requirement or wish to discuss this topic please don’t hesitate to CONTACT US.